KEFAI high speed automatic sachet chilli powder packing machine for 1g 2g 3g 4g 5g 10g 15g sachet filling sealing packaging.

KEFAI High-speed automatic chili powder sachet packing machine is designed for the automatic packing of cumin powder, pepper powder, garlic powder, onion powder, soup, chicken stock, chili powder packaging. It can be done three side sealing and four side sealing sachet packaging machine.

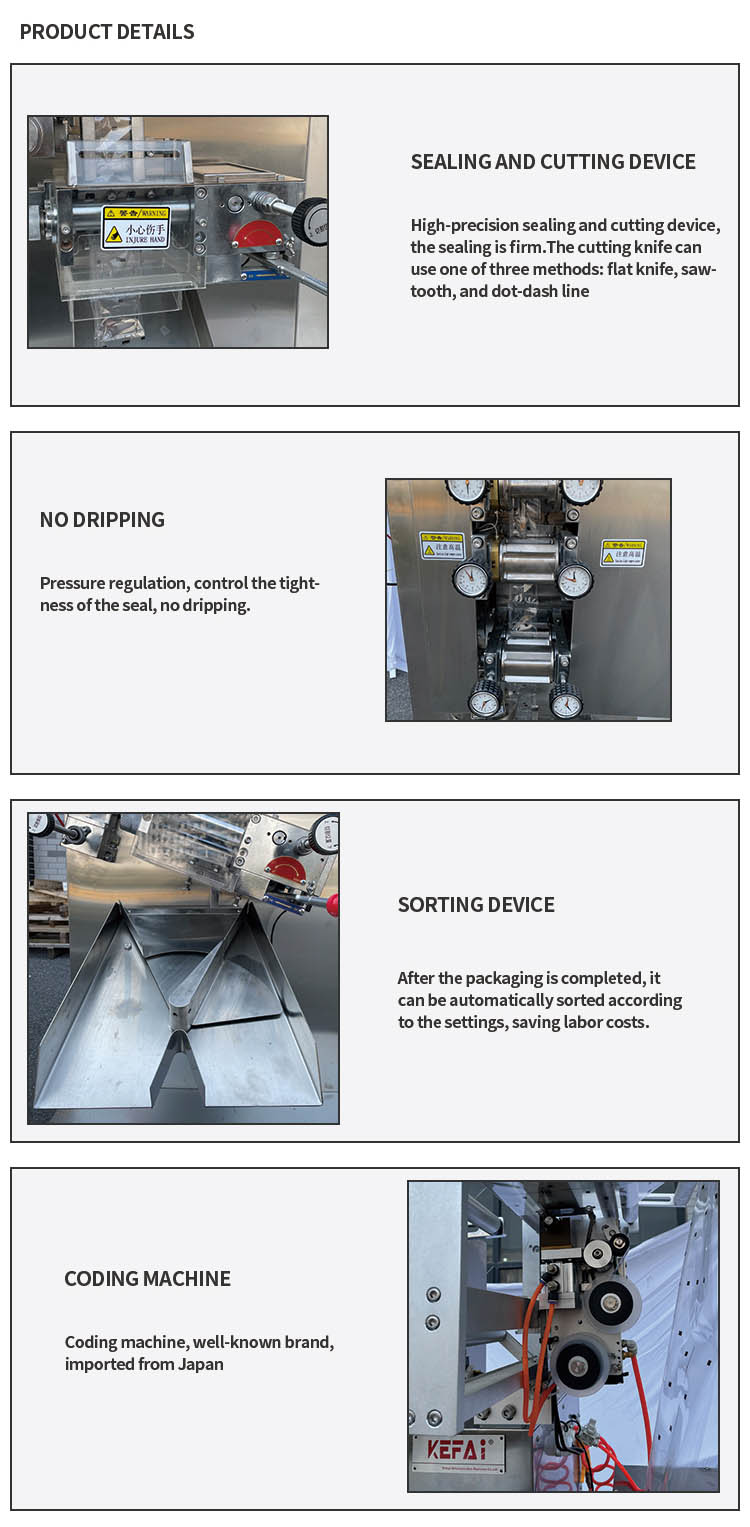

KF02-PD VP series mechanical breakthrough adopts a localizable high performance double frequency conversion PLC control system, through "man-machine dialogue", making the adjustments for replacing products become simple, accurate, and stable, English interface makes the setting operations simple, intuitive, and reliable. Cut-off methods can use each flat knife, serrated knife, and point marking knife as a requirement. And this chilli powder packing machine is equipped with an ease open bag cutting device.

Main Features

KEFAI High speed sachet adopts one set of vertical hot roller devices and one set of horizontal hot roller devices. Roller sealing ensures an artistic and neat seal and chessboard pattern is complete and unintermittent. Various filling devices could be chosen, such as Volumetric Cup Filler, Auger Filler and Tablet Counting Filler. There are three types of cutting functions: plain cutting, sawtooth cutting, and perforation cutting. This machine is also equipped with a tear notch for convenient bag opening. PLC control, touch screen displays running status. Vertical sealing unit driven by variable-frequency motor, realize step-less adjustment of packaging speed within the rated range. Horizontal sealing unit driven by servo motor, realize stepless adjustment of bag length within the rated range. The bag length can be set on a Touch screen, and length adjustment is easy and convenient. Intelligent photocell positioning control system with the function of automatic positioning of the first bag. Eliminate the influence of signal disturbing caused by abnormal eye-mark pattern and bad print of film, to ensure stable operation. Automatic adjustment function for noneffctive cutting, solves the problem of multiple machine-stopping adjustments and waste of film, improving working efficiency and ensuring the good appearance of bags.

Application

KEFAI's automatic packing machine can package many powder products, such as spices, seasoning mixes powders, herbal supplements, vitamins, detergents, and so on.

Technical Parameters

| Item | KEFAI Chilli Powder Packing Machine |

| Length | 50-180mm |

| Width | 30-95mm(3-side seal) 35-100mm(4-side seal) |

| Filling Capacity | 30-95mm(3-side seal) 35-100mm(4-side seal) |

| Filling Capacity | 0.5-30ml/g |

| Packing Speed | 100-200pcs per min |

| Power | 3kw/ AC380V |

| Dimension | 1200*1000*1800mm(L*W*H) |

| Weight | 450kg |

| Packaging film | PET/AL/PE, PET/PE, OPP/CPP, etc. composite film |

| Parameters of Film Roll | Outer Diameter≤400; Inner Diameter φ75 |

Details

Video

Click to Watch Our High Speed Packing Machine for Chili Powder

Company Advantage

KEFAI as a professional manufacturer of chili powder packaging machine, pay great attention to the quality of our products. We use high quality materials and components to ensure that our chilli powder packing machine can be used stably for a long time. Our factory has a rigorous quality control process and testing standards, and each chili powder filling and sealing machine is subjected to stringent testing and inspection, we ensure that our chilli powder packaging machine meets international quality standards and can meet customers' expectations.

Find our other chili powder packing machines at Kefaimachinery.

Our Customer Feedback

FAQs about Chilli Powder Packing Machine

1. What are the tasks that can be done automatically by the automatic chili powder packing machine?

KEFAI's chili powder packing machines can automate several tasks, including automatic dosing and filling of chili powder, automatic sealing, and automatic printing of dates and production lot numbers. These automated functions can greatly increase productivity and reduce labor involvement.

2. How to adjust chili powder packing solution for different sizes of chili powder pack?

Our chilli powder packing machines usually have adjustable parameters and components, such as a metering device and sealing temperature. You can adjust the corresponding parameters according to your chili powder product specifications and requirements to ensure accurate metering and filling.

3. Can the chili powder packaging machine automatically detect defects or foreign objects in the bags?

Yes, KEFAI's chilli powder filling machines are all equipped with advanced inspection systems that can automatically detect defects or foreign objects in the bags. The packaging machine for chilli powder can monitor the quality of the bags in real time and join to find out such as leakage of air holes, tears, breakage or incomplete sealing of the bags, the chilli powder filling machine can automatically reject these defective bags. In addition, the chili filling sealing machine can detect foreign objects in the bags through optical sensors. Once foreign particles, metal flakes or foreign fibers are detected, the powder pouch packing machine will sound an alarm and stop running.

If you have any questions about the Chili Powder Packaging Machine, You can ask us for help!