China Cosmetic Packaging Machine Factory

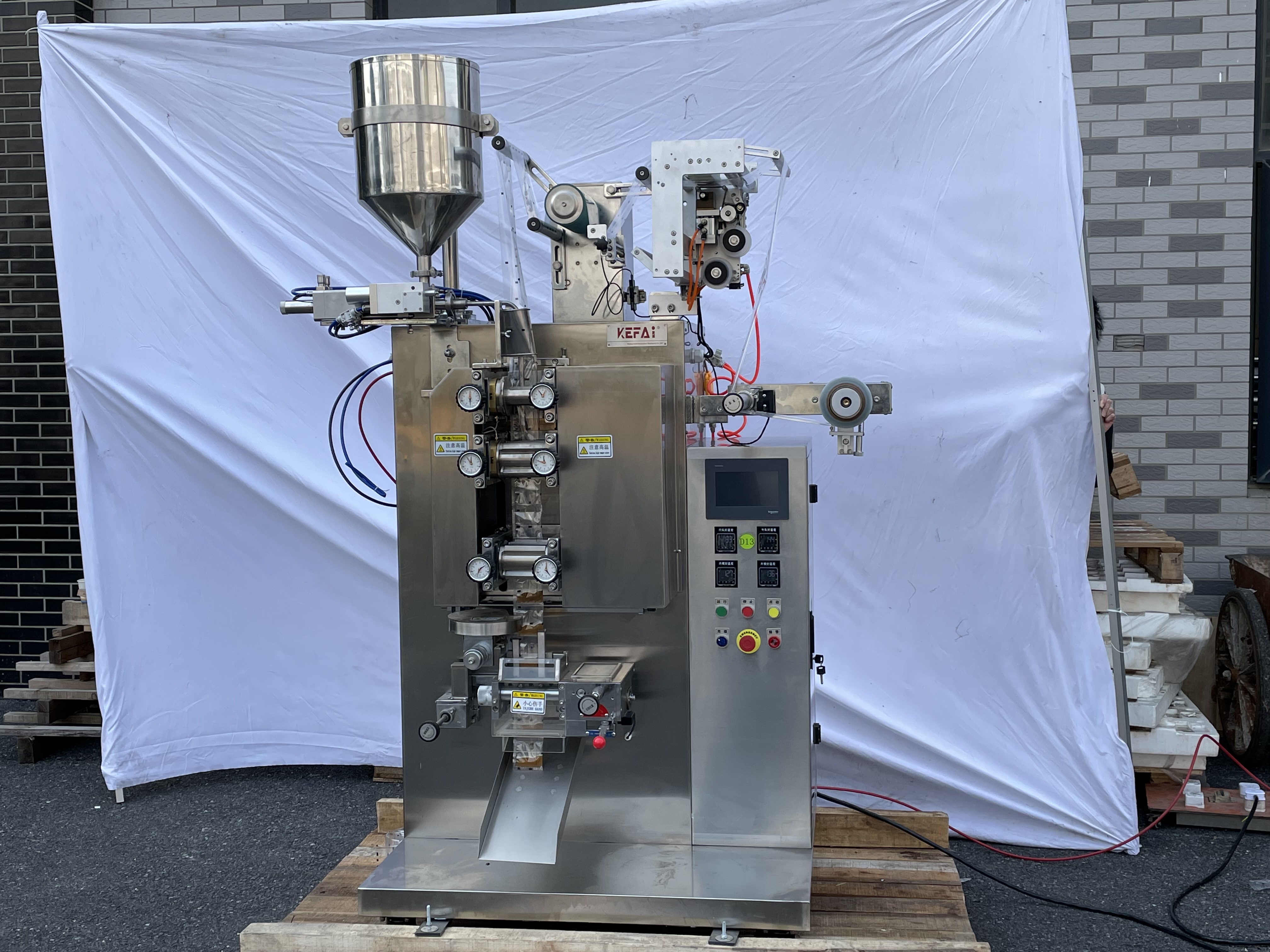

The cosmetic packaging machine is an advanced high-speed roller-type packaging equipment, especially used to pack various cosmetics and personal care products, such as cosmetic liquids, lotions, facial masks, skin care products, etc., which are usually in the form of sachets or small packaging bags. Packing cosmetics jobs include filling, sealing, labeling, and packaging cosmetics to ensure that each product can be perfectly packaged. Cosmetic packing machinery can meet your needs for quality and consistency.

KEFAI Cosmetic Packaging Machines are highly automated and productive. These high speed packing machine can quickly and accurately pack various cosmetics into sachets. The high speed pouch packing machine uses a high-precision control system to ensure that the capacity and sealing of each pouch are consistent. On the one hand, packaging machines for cosmetics are usually able to pack at a speed of hundreds of sachets per minute, which is suitable for large-scale production needs. On the other hand, the use of this sachet packaging machine can provide high-quality paste packaging.

- Adapt to different packaging materials

- Easy to replace products

- Suitable for a variety of cosmetics

- Visual control

Description

The high-speed roller-type cosmetic pouch packaging machine is an ideal choice for cosmetic manufacturers and packaging companies. This kind of cosmetic packaging machine can produce various packaging styles, including three-sided sealed bags, four-sided sealed bags, combined bags, etc. Choose various types of high-speed packaging machines according to your specific product needs. Cosmetic packaging equipment can help improve production efficiency, reduce packaging costs, and ensure that products are presented to consumers in a high-quality manner.

Features

Main Features

◆ The machine has one set of longitudinal roller sealing devices, one set of transverse roller sealing devices, and one set of transverse roller reinforced sealing devices.

◆ The longitudinal sealing pattern adopts a continuous checkerboard pattern with an anti-leakage line. Horizontal sealing is a checkerboard pattern with a leakage-proof line or flat sealing with a leakage-proof line.

The working process of the whole machine includes bag making, longitudinal sealing, filling, transverse sealing, transverse reinforcement sealing, easy-tear notch making, cutting, and other main processes.

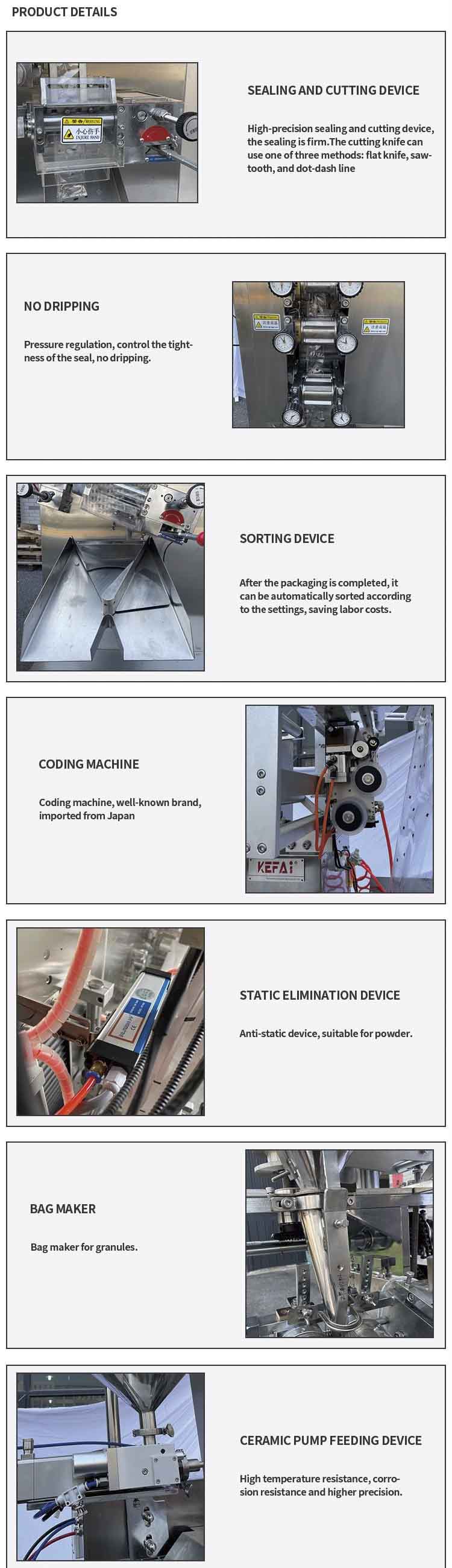

◆ The cutting knife can be one of the three ways: flat knife, serrated, and point scribing.

◆ Feeding device will be selected according to the physical condition of the packaged material, including magnetic pump M for liquid filling, Hiba pump H and Rotary pump R for homogeneous viscous body filling, and piston pump P for viscous body filling containing particles.

◆ The whole machine adopts PLC centralized control, human-machine interface operation and display of working conditions, working speed is controlled by frequency conversion speed regulation, sealing temperature is controlled by intelligent temperature controller.

Specification

item | Content | Remarks |

Bag length range | 45~180mm | Ordering bag length +/-30m (can be adjustable) |

Bag width range | Three side seal: 30~95mm Four side seal: 35~100mm | Changing the package width requires changing the forming machine |

Packing speed | 30~120 packs/min | Depends on materials and specifications |

Power consumption | 3kw/AC380V 3P+N | |

Machine size | L1200mmW1000mmH1800mm | |

Machine weight | 450kg | |

Packaging material | Various kinds of composite packaging film are available. Outer diameter of rolled film≤400; inner diameter of rolled filmφ75. | |

Filling method | Liquid: Magnetic pump metering unit Homogenized viscosities: Hyperion pump metering units, Rotary pump metering unitsViscosities with particles: Piston pumps | Selected according to the physical condition of the packaged material. |

Optional equipment | Thermal embossing device, coding machine, | Separate order |

Deatils images

For More Details, Please Send Us An Inquiry.

Related Machines

Cosmetic Sachet Packaging Machine: A cosmetic sachet packing machine is a special kind of equipment, commonly used to accurately and effectively pack cosmetic samples, and disposable sachets. These automatic cosmetic packing machines are usually used in the beauty and personal care industries to pack various cosmetics, including creams, lotions, gels, shampoos, etc., in convenient and portable sachets.

Cosmetic Blister Packaging Machine: Cosmetic blister packing machine is an indispensable part of the cosmetic industry. Blister equipment can provide efficient and attractive cosmetic packaging solutions, helping to protect and sell cosmetic products.

Cosmetic Tube Packaging Machine: In order to fill and seal cosmetic products, such as creams, gels, lotions and ointments, into the extrusion tube, we recommend that you use this cosmetic tube packaging machine. Cosmetic tubes are a common and convenient packaging choice for various personal care and beauty products.

Cosmetic Bottle Filling Machine: The bottle filling machine can be equipped with a capping machine and labeling machine to combine a production line.

Mascara Filling Machine: The mascara filling machine can not only accurately and efficiently pour mascara into the mascara tube or container, but also ensure the consistency of cosmetic product quality and minimal waste.

Perfume Filling Machine: Perfume filling machines are designed to accurately fill perfume or perfume into bottles. The use of perfume filling capping machines is very important in the cosmetic packaging industry.

Lipstick Filling Machine: Lipstick filling machine is specially designed equipment for filling and forming lipstick into lipstick tubes. Its most important feature is accurate filling.

KEFAI Advantages

KEFAI is a manufacturer with more than 10 years of experience in the packaging industry. In the cosmetic packaging machinery market, KEFAI has a great reputation. Over the years, we have cooperated with many manufacturers at home and abroad to solve the packaging problems of many cosmetic ointment products. KEFAI can provide you with a variety of cosmetic packaging solutions, including bottled and sachets. We can have the best equipment for packaging all kinds of cosmetics.

You can click here - KEFAIMACHINERY to find other related cosmetic packaging equipment.

Our Customers Feedback

FAQs about Cosmetic Packaging Machine

1. Is the cosmetic packaging system suitable for small-scale production?

Yes, our cosmetic packaging machines come in various sizes and automation levels, suitable for small-scale and large-scale cosmetic production.

2. Does the cosmetic packaging function adapt to different types of cosmetic formulas?

Yes, these machines can make various cosmetic formulas, including liquids, creams, gels, powders, etc. As long as the hopper is replaced, different types of materials can be packaged.

3. How to choose a suitable cosmetic packaging machinery for my company?

Choosing the right machine depends on your specific production needs, the type of cosmetics you produce, and the packaging format you want. When you purchase a suitable cosmetic packaging machine, please consider factors such as production volume, product characteristics, and budget. Please tell us your various production requirements. We can customize suitable packaging machines for your cosmetic production industry.

4. How can these cosmetic packing solutions help ensure product quality and consistency?

Cosmetic packing machines help maintain product quality and consistency by ensuring accurate filling, precise sealing, and labeling, thereby reducing the risk of contamination and ensuring that each finished product is of the same weight.

If You Want To Know More Details About Our Cosmetic Packing System, Please Send A Quote Request!