What Is Packing Machine?

Packing machines play an important role in modern industry and are used in a wide range of sectors. Automated packing machine plays a key role in the packaging process of products in industries such as food and beverages, pharmaceuticals, consumer goods and many more. Packing machinery is used to ensure that products can be packaged in an efficient, accurate, and consistent manner to meet market demands and consumer expectations.

So what is packing machine?

Packaging equipment is an automatic packing and sealing machine that can complete all or part of the packaging process for products and commodities. This is an automated packaging process and equipment. The packaging process of the auto packing machine includes filling, coding, sealing, wrapping and other major processes, as well as its related processes before and after, such as cleaning, stacking, and disassembly. Use a packaging machine to put the product in a suitable container for storage, transportation or sale. The purpose of a packaging machine is to automate the packaging process, in order to efficiently and accurately place packaged products into various containers for storage, transport or sale. The use of machines for packaging to package products is intended to increase productivity, ensure product quality and consistency, reduce labor intensity and reduce human error to meet the needs of mass production.

How packing machine works?

Although the working principles of different types of packaging equipment systems and different packaged products will vary, in general, the typical packaging machine works as follows:

Product feeding:

The packer receives products in various forms, such as solid items, liquids, powders, or granules, through a hoist, hopper, or other feeding system.

Container Preparation:

The packer prepares the container in which the product will be packaged. This may involve automatic bag making, clamping open pre-made bags, erecting cartons or boxes, and various other packaging situations.

Filling:

The product is filled into the container by means of a filling system. Depending on the type of product and packaging requirements, this can be done using volumetric fillers, piston fillers, liquid pumps or other appropriate methods.

Sealing:

After filling the packaging machine seals it. This is typically done by heat sealing, glue sealing, zipper sealing, cap application, or other sealing methods specific to the package type.

Labeling and coding:

Some packer machines may come with an integrative labeling or coding system, if needed, to facilitate labeling, barcoding, or dating of containers.

Inspection and quality control:

Packaging machines may include inspection systems to check the quality of the package, such as to ensure proper sealing, correct fill levels, or the absence of contaminants. Any defective packages may be automatically rejected or flagged for manual inspection.

Conveying and Output:

Packed finished products are conveyed out of the packer for subsequent packing, boxing, processing operations, etc.

The basic functions of the package solutions include:

Packaging material supply:

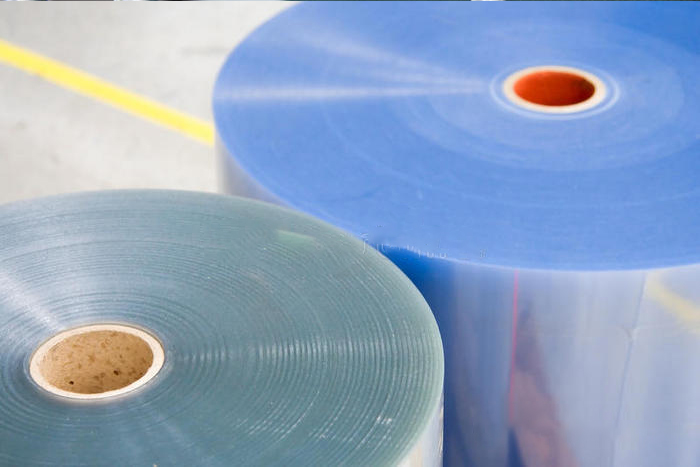

Containers such as plastic roll film, pre-made bags, glass bottles, box cartons etc. are guided to the working area of the automatic packing machine by means of appropriate devices.

Product feeding:

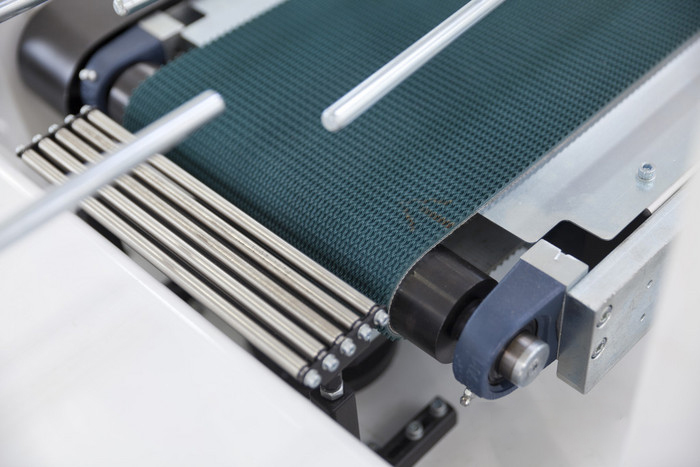

The product to be packed is conveyed to the corresponding position of the automated packaging equipment for packing by means of a conveyor belt, conveying system or other device.

Packaging process:

The packing sealing machine performs a series of operations such as automatic filling, sealing, labelling, strapping and wrapping according to pre-set parameters and programs to ensure that the product is placed safely in the container.

Control system:

The pack machine is equipped with a control system, usually a PLC (Programmable Logic Controller), to monitor and control the packaging process. It allows the speed, positioning, timing and other parameters of the packaging machine to be adjusted to suit different products and packaging requirements.

The packaging machine working principle involves several key components working together, including sensors, motion control systems, conveyors and filling devices.

The following are descriptions of the packaging machine parts:

Sensors:

Sensors play a key role in packaging machines and are used to detect and sense the position, status and properties of products and packaging materials. For example, photoelectric sensors can be used to position products for packaging operations. Weight sensors can effectively measure the weight of the product to ensure that it is filled correctly. Temperature sensors can be used to monitor the temperature during the sealing process to achieve a tight seal.

Motion control system:

The package solution's motion control system includes devices such as servo motors, drives and controllers. They work in tandem to control the movement and operation of the package equipment. Through accurate position control and motion coordination, the motion control system enables the packer to perform each step of the wrapping operation with precision.

Conveyor belt:

The conveyor belt is an important component of the wrapping machine and is used to transfer the product to the next position for wrapping. The speed of the conveyor belt can be adjusted at any time.

Filling devices:

Depending on the characteristics of the product and the packaging requirements, different filling devices are available. There are filling devices suitable for powdered products, but also for granules, liquids and pastes.

The classification of automated packing machines can be classified according to the following popular attributes:

automation level, application type, packing type, molding type, molding function, drive type, material type, packaging container, packaging material.

Level of automation:

Based on the level of automation, packaging machines can be classified as automatic packaging machines, semi-automatic packaging machines, and manual packaging machines.

Application type:

The product packaging solutions will be classified according to the type of application, and can be divided into casual food dairy products, fruits and vegetables, rice and noodles, spices, cosmetics category, cleaning, detergents, tea, beverages, fish and meat and other industry product packaging.

KEFAI has many related packing machines, such as automatic snacks packing machine, meat packing machine, automatic sugar packing machine, sausage packing machine, seed packing machine, vegetable packing machine, beans packing machine, biscuit packing machine, book packing machine, ice packing machine, automatic flour packing machine, automatic egg packing machine, automatic bread packing machine, and so on.

Packaging type:

The type of classification of automated packaging machines can be classified into filling and sealing machine, forming filling and sealing machine, double sealing machine.

Forming type:

To classify the packaging solution according to the type of molding, it can be divided into bag molding packaging machine, box molding packaging machine, melt molding packaging machine, blister molding packaging machine, and bottle molding packaging machine.

Forming function:

The forming function of packaging equipment solutions is generally divided into sealing, filling, forming, three functions.

Drive type:

The packaging automation solutions will be categorized according to the type of application, which can be divided into electric, pneumatic, motorized, hydraulic, manual

Material type:

According to the type of application of packaging machine classification, can be divided into solid packing machine, granular packing machine, powder packing machine, liquid packing machine, paste packing machine, and gas packing machine.

Packaging containers:

The packaging machine is suitable for packaging containers such as bags, cartons, bottles, cans, barrels, etc.

Packaging materials:

The packaging materials for automated packaging solutions usually use film, plastic, composite materials, paper, bamboo, wood, metal, aluminum foil, fabric, glass, and ceramic.

The main types of multifunctional packaging machines are:

- Automatic pillow pack packaging machine is a common type of flow pack machine, also known as a horizontal packaging machine or flow pack wrapping machine.

The horizontal pillow packing machine is renowned for its efficient packing speed and superior automation. Flow packing machine is one of the flexible packaging solutions that can quickly place the product into the packaging material, seal and cut it for an automated packaging process.

The automatic pillow packing machine has the flexibility to adapt to different sizes and types of packaging material, as well as to pack formats such as single product packs, multiple product packs, etc. as required.

The pillow wrapping machine is suitable for a wide range of products of different shapes and sizes, such as food, daily necessities, and pharmaceutical products. Specifically suitable for packaging blocks, granular or solid food products such as biscuits, chocolate bars, bread, and sweets. As well as soap, soap, wet wipes, disposables, etc.

- Automatic vertical packing machine is a common type of the best pouch packing machine. It is divided into small bag vertical form fill seal packing machine and large bag vertical form fill sealing machine. Also the type of material can be divided into vertical powder packing machine, vertical granule packaging machine and vertical liquid paste packaging machine. The vertical pouch packing machine is renowned for its compact design and efficient packaging speed. It typically takes up less space and can be installed and operated in limited production environments.

It has the flexibility to adapt to different bag sizes and types, including a wide range of sachets and medium sized to large sized bags, and can be adapted to suit the packaging format, such as sealing methods, pack sizes, etc. It is possible to pack a wide range of snacks, nuts, cosmetics, shampoos, detergents, laundry detergents, and other products.

- Rotary Cup Filling and Sealing Machine completes the filling and sealing process by means of a rotating table. The automatic cup filling and sealing machine is an aseptic packaging machine and the rotary filling and sealing machine usually has multiple workstations, allowing multiple products to be filled and sealed at the same time, improving packaging efficiency and making the filling and sealing process more stable, reducing the risk of product damage and packaging failure. Rotary fill and seal machines are widely used for packaging cups of tea, coffee capsules, yogurt, and other liquid materials. By the way, we also have a k cup filling and sealing machine.

HFFS Packing Machine is a composite film automatic packaging machine. Horizontal packing machine uses flowpack automatic bag making, filling, sealing form packaging a variety of powders, sauces, and granules of automatic packaging.

- Premade Pouch Packing Machine is mainly suitable for doypack bags, flat bags, hanging hole bags and shaped bags filling and sealing, the choice of different discharging devices can be packaged for different products can be packaged liquid, powder, granules, suspensions, and other kinds of materials. Premade bag packing machine instead of manual packaging, for large enterprises, small and medium-sized enterprises to achieve packaging automation.

- Blister Packing Machine is a primary packaging equipment used to put products to be packaged into a blister. Blister packaging consists of a clear plastic blister to hold the product and a bottom card to seal the blister. The use of a blister pack sealing machine can provide better protection to the products and reduce the risk of damage during transportation and storage. A blister pack machine is widely used in industries such as electronics, furniture, glassware, ceramic products, machine parts, etc. to protect products from external shocks and vibrations.

- Vacuum Packing Machine also known as a vacuum sealer, is a device used to remove air from a bag to achieve a vacuum seal. Vacuum packer machine is commonly used in the food industry to extend the shelf life of perishable foods. Vacuum packing machines are suitable for products with vacuum packaging requirements suitable for all sizes and dimensions. Vacuum pack machines can meet a wide range of packaging needs from small scale operations to large scale industrial production. Packaging machine operator is easily able to use the vaccum pack machine so it is a great packaging machines for small businesses.

Packaging machines offer many advantages and benefits that have a positive impact on both the production process and the quality of the product.

Here are some of the main advantages of automatic packing machines:

Increased productivity:

The machine for packaging is able to complete the packaging process at high speed, continuously and consistently, greatly increasing productivity. Unlike manual packaging equipment. The automatic pouch filling and sealing machine can replace manual packing, completing packaging tasks more quickly and reducing labour costs. The advanced packaging solutions are able to complete a large number of packaging tasks in a shorter period of time, thus saving time.

Reduced human errors:

The automated process of the packaging machine reduces the occurrence of human errors and the smart pack machinery can precisely control the packaging process to ensure the quality and consistency of the product. By using precise sensors and control systems, the packer can perform the packaging task accurately, avoiding product weight errors in human operations.

Enhancing brand image:

Fully automatic packaging machines maintain product tightness, prevent contamination, protect against damage, and ensure product integrity during transport and storage. By using advanced packaging machines, beautiful, consistent, and professional product packaging can be achieved, enhancing the brand image. This results in attracting attention and increasing the marketability of the product.

Then maybe you are confused:

How packing machine works?

Here we will present the working principles of several specific packaging machines based on:

Vertical Form Fill Seal (VFFS) packaging machine:

The VFFS packaging machine is a common automated packaging machine capable of packaging granules, powders, and liquid pastes. It works as follows:

- First, the VFFS machine passes the rolled packaging material (usually plastic film) through a series of rollers and bag makers to form a vertical tubular bag.

- The material enters the bag through a feed system, either by means of a vibrator or a screw feeder.

- The filling device of the packaging machine fills the bag with the material precisely.

- After filling, the top of the bag is sealed and closed by heat or pressure sealing.

- The final result is a completely finished bag.

Horizontal Form Fill Seal (HFFS) packaging machine:

HFFS packaging machine is also a practical automatic packaging machine for all kinds of solid, liquid, viscous, and powder materials. The working principle is as follows:

- The HFFS machine draws plastic film or aluminum foil rolls to form horizontal pouches.

- The material to be packaged is filled precisely into the bag in a corresponding manner.

- After filling, the bag is sealed by heat or pressure.

- The final complete bag is realized by cutting with a cutter.

Rotary Premade Pouch Packing Machine:

Rotary premade bag packing machine with high packing speed and flexible operation is equally suitable for various forms of products, for different types of products and packing sizes including granules, powders, liquids, and pastes. The automatic premade pouch packing machine working principle is as below:

- Premade bags are supplied to the rotary table by clamping

- The material enters the bag through a feeding system, either by means of a conveyor belt, an injection unit, or a can filler.

- A filling device fills the bag with product, usually by means of a rotary table or an injection unit, etc.

- Once the filling is complete, the bag is sealed and closed by heat or pressure methods.

- The finished product is finally lowered and discharged from the table.

How To Choose Packing Machine?

Choosing the right integrated packaging machinery is critical to an efficient and effective packaging operation. Here are some key factors to consider when selecting machinery for packaging:

Consider your product’s specific packaging requirements:

Consider the size, shape and material of your product, as well as the form of packaging required (e.g., pouches, cartons, bottles, etc.), the speed of advanced packaging equipment, and the volume of packaging.

Consider the type of machine:

There are various types of advanced packaging machinery, such as vertical form fill seal machine (VFFS) machines, horizontal form fill seal machine (HFFS) machines, vacuum packaging equipment, automatic blister packing machine, and so on. Among the many types of packaging machines available, you need to choose the one that suits your product and packaging requirements.

Consider machine speed and capacity:

Consider the speed and productivity of the protective packaging solutions in relation to your required production output to ensure that the performance of the innovative packaging solutions is capable of realizing your production needs.

Consider budget and cost:

Determine your budget for the creative packaging solutions first, and then find the best global packaging solutions between cost and functionality by comparing the features, performance, and price of different machines.

Consider the quality and safety of the machine and compliance:

When choosing a packaging machine you need to check whether the solution pack has quality international certifications and standards compliance, consider whether the packaging machinery equipment contains features such as safety guards, and emergency stop buttons, and whether it complies with relevant safety regulations. In this way, you can ensure that the multi packaging solution meets industry requirements.

By considering these essential factors, you can choose packaging equipment and machinery that is perfect for your business.

How to maintain the packaging machine?

Regular maintenance and repair of the automatic filling packing machine can ensure the stable operation of the packaging line equipment every time, and can effectively extend the packaging equipment services life. Here are some steps and precautions related to package machine maintenance:

Cleaning:

Use suitable cleaning agents and soft cloths to clean the dust, dirt, and residues on the external and internal parts of the automatic packing system every time you clean. Be careful to avoid using too much water or chemical solvents that could damage the pack equipment.

Lubrication:

It is important to add the proper lubricant to the machine's lubrication points on a regular basis, according to the packing machinery manufacturer's recommendations. You need to make sure that you use the right type and amount of lubricant to keep the equipment packer running smoothly and reduce frictional resistance.

Tighten Bolts:

Check the bolts and fasteners on the filling and packaging equipment to make sure they are all securely fastened. If you find loose bolts please torque them promptly to prevent the machine from loosening or being damaged during operation.

Transmission System:

Regularly check the packaging machine's transmission system for proper functioning, including drive belts, chains, and gears, to ensure that they are free of damage, wear, or looseness. Also, adjust or replace as needed.

Electrical System:

Check the electrical system of the automatic filling and sealing machine, including wires, terminals and switches. Make sure there are no loose or exposed wires to ensure safe electricity.

Preventive Maintenance:

The key components of the pack system, such as sensors, seals, blades, etc., should be replaced or maintained periodically according to the manufacturer's recommendations. Follow the maintenance schedule and recommendations provided by the packaging machine manufacturer to ensure proper machine operation and optimum performance.

Train Operators:

The packing machine operator needs to be adequately trained in the proper operation and maintenance of the packing system. KEFAI provides the necessary training and documentation to enable operators to understand common troubleshooting methods and basic maintenance procedures.

Record maintenance:

Package equipment engineers need to write up detailed maintenance records, including the date and item of maintenance, information about the operation and the person performing it. It will help track the maintenance program and identify any potential problems.

In addition to the above measures, packaging equipment companies need to follow specific machine maintenance guidelines and operating manuals provided by the manufacturer. Perform regular preventive maintenance and deal with any malfunctions or abnormalities in a timely manner to ensure that the automatic wrapping machine is always in good condition and provides reliable performance.

Case Study on Packaging Machines

Then, let me present a case study of a relevant packaging intelligence solutions:

In the past, a food company that relied heavily on manual operations for their packaging process reported that they were currently experiencing low productivity, inconsistent packaging quality, and high labor costs. To improve this situation, they decided to purchase an advanced multifunctional automatic powder packing machine from KEFAI. The introduction of an automated packaging line in the industry is able to automatically perform tasks such as product metering, bag forming, filling, sealing and labeling, and finally transferring the finished product via a conveyor belt. The food packaging equipment company's production efficiency has significantly increased since then. The automated packaging machine can handle large quantities of product per minute and maintains the quality of the product while saving costs and being able to achieve higher profitability.

Technological developments and trends play an important role in the packaging machine sector, driving innovation and improvements in the packaging process. As automation technology continues to develop, packaging machines are becoming increasingly intelligent and automated. In the context of sustainable development, there is a growing interest in environmentally friendly integrated packaging solutions. Packaging machine manufacturers and users are committed to developing and using renewable, biodegradable, and recycled materials in order to reduce the environmental impact of packaging. In addition, optimizing the design and operation of industrial packaging machines to reduce resource consumption and waste generation is also an important concern. What's more, fill and seal machine programming algorithms can be applied to packaging machines to improve packaging efficiency and accuracy through learning and optimization.

In summary, fill pack solutions play a key role in modern industry. Packaging equipment shows us the progress of modern society. Through automation and efficient packaging processes, automatic packaging machines increase productivity, reduce human error, ensure product quality and consistency, reduce labour costs, and save time and resources. As technology continues to evolve, the packing system sector will continue to see new innovations and trends, such as the use of automation and machine learning, the rise of sustainable packaging solutions, and the impact of digital technology, which will further enhance the effectiveness and sustainability of all pack machinery and drive the entire packaging industry in a smarter, greener and more efficient direction.

Welcome to ask KEFAI for more information about packaging machines!