A Trustworthy HFFS Packaging Machine for Liquid

Liquid Hffs (Horizontal Form Fill Seal) packaging machine is a packing equipment specifically suitable for packaging liquid products. Hffs solutions are commonly used in the food and beverage, pharmaceutical, cosmetic and household chemical industries, and can be used to package a variety of stand-up pouches, spout pouches and other small bags of liquid products.

KEFAI horizontal form fill seal machines are so powerful that it can easily package liquid and paste products. A horizontal form fill and seal machine for liquid and paste creates bags from a roll of flexible packaging hffs film material. The HFFS equipment then fills and seals the pouch with the liquid or paste product, creating a secure and perfect package. Automatic HFFS machine can basically pack all kinds of bags well. If you use this intelligent packaging machine, you will reap high-packaging quality products.

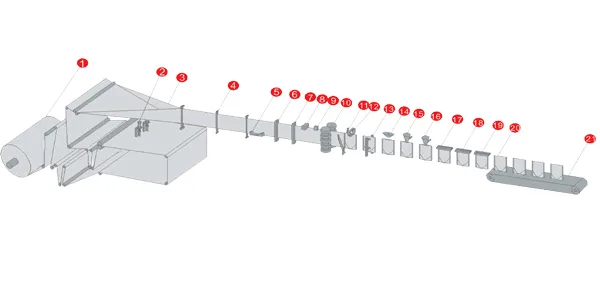

HFFS Machine for Liquid: The horizontal form fill seal machine has become a popular choice for companies in the liquid packaging industry through its own wide range of excellent features. And our hffs pouching machine is very popular in various industries. We understand that the needs of each customer are unique, so we provide customized packaging solutions to design and manufacture the most suitable liquid HFFS machine according to customer requirements and product characteristics. 1.Film Unwind 2.Bottom Hole Punching 3.Bag Forming 4.Film Guide 5.Bottom Seal 6.Vertical Seal l 7.Vertical Seal II 8.Tear Notch 9.Photocell 10.Servo Advance 11.Cutting 12.Pouch Catching 13. Pouch Opening 14.Air Flushing 15.Filling I 16.Filling II 17.Top Seal I 18.Top Seal II 20.Finished Product 21.Outlet Specification Related Machines Powder HFFS Packaging Machine: This is a smart horizontal form-fill-seal packing equipment for packing powder material. It can efficiently transfer powdered items, such as coffee powder, flour, milk powder, etc. The HFFS machine is designed to take into account the special characteristics of powder items and is able to control the flow of powder and prevent dust generation. What's more, according to the characteristics of different powders, the machine can adjust the filling speed and filling method to ensure stable packaging effect. Granule HFFS Packaging Machine: Granule material can be packed by using this hffs packaging machine. It can efficiently fill and seal granular items, such as coffee beans, peanuts, candy, etc., into bags. Granule HFFS machines have multihead scales or weighers or counters that enable accurate control of the weight or quantity of granular items in each bag, ensuring that each package meets the intended requirements. Advantage Good Production Presentation One of the key advantages of the liquid horizontal packing machine is its high efficiency and productivity. It can achieve high packaging speeds, especially for packaging large quantities of liquid products in a relatively short period of time. This is particularly beneficial for companies with high production demands. In addition to this, it allows customization options such as printing additional features like product production dates. Video Click to Watch KEFAI Liquid Pouch HFFS Packaging Machine Video Contact Us KEFAI has a wealth of experience and a professional technical team, and has accumulated many years of professional knowledge in the field of Hffs packaging machines. We are committed to providing high-quality, reliable and efficient liquid HFFS machines to meet customer needs. Unlike used hffs packaging equipment, we use high-quality materials and advanced manufacturing technology to ensure that liquid/paste HFFS machines are brand new, with high stability and long service life. We carry out strict quality control and testing to ensure that each machine meets high standards You can also search our liquid HFFS packaging machines at Alibabaand Made-in-China. Our Customers Feedback "I have compared many horizontal form fill seal machine manufacturers, and I finally chose KEFAI's hffs machine. Not only because their hffs machines are the most cost-effective, but also KEFAI's customer service staff are very professional and very good, and I get along with them very well." —— Mr. Gary, a customer from Ireland. "KEFAI's automatic liquid HFFS machine is really an excellent device!Its production efficiency is very high, and we have a certain advantage in being able to produce more products quickly than other factories.Most importantly, it has a low error rate and can run work safely and efficiently for a long time.We are very satisfied with this purchase." —— Mr. Fred, a customer from Norway. "We are very satisfied with the performance of KEFIA's HFFS packaging machine for liquid products. Its automation function makes the entire packaging process more efficient and smooth.At the same time, the packaging quality of our products has been significantly improved.Thank you very much for KEFAI's special help in this process." —— Mr. Joseph, a customer from Sweden. FAQs about Liquid HFFS Packaging Machine 1. Do liquid HFFS machines need to use specific types of packaging materials? 2. Can liquid HFFS machines adapt to different packaging specifications and sizes? 3. What is the production capacity of the liquid HFFS packing machine for liquid and paste? 4. What kind of maintenance and maintenance does the liquid HFFS machines need? Features

Yes, liquid HFFS packer machines usually need to use specific types of packaging materials suitable for liquid packaging. These materials are usually plastic films that are resistant to liquid penetration, such as polyethylene (PE) films or composite materials. These materials have good sealing properties, which can prevent liquid leakage and oxygen from entering the packaging, while maintaining the freshness and quality of the product. When choosing suitable packaging materials, it is recommended to communicate with suppliers in advance to ensure that materials that meet product characteristics and packaging requirements are selected to avoid the problem of poor packaging effect in the future.

Yes, liquid HFFS packaging solutions can be adapted to different packaging specifications and sizes. It has the function of adjustable parameters, and the packaging size can be adjusted as needed. By replacing suitable molds and adjusting the settings of the hffs machine, packaging of different sizes and shapes can be achieved. Therefore, the liquid HFFS system is very flexible and can adapt to the packaging needs of different products.

The production capacity of liquid and paste HFFS packaging machines depends on a number of factors, including the viscosity of the product, packaging size and packaging materials. Generally speaking, the production speed of liquid HFFS machines can reach hundreds to thousands of packages per minute, and the specific adjustments can be made according to customer needs.

As we all know, regular maintenance and maintenance of HFFS packing machines is very necessary. It includes cleaning the various parts of the machine, inspecting and replacing worn parts, lubricating moving parts, and regularly calibrating and adjusting the parameters of the machine. We provide the operation manual and maintenance guide of the machine for your reference.